Materials

All of our printers use 1.75mm filament.

We store most of our filament in the Rockstar fridge. The compressor on the fridge is disabled and there are a ton of silica packets in there, so it helps make for a dry, dust-free environment. We have mostly PLA, some ABS, a little PETG, and maybe one or two spools of other specialty filamnt (TPU, Carbon Fiber, etc). Filament in the fridge is pretty much up for grabs unless someone's name is on it. As with all consumables in the space, don't be a jerk – if you use a ton of filament, please help replace some.

Software

- Our recommended software. It is open source and can be used with all four of our current FDM printers.

- After you click the link above, you can find the OrcaSlicer download for your OS at the bottom of the page under "Assets."

- Be sure to download OrcaSlicer ONLY from this github page, which is their official source. Avoid "-orcaslicer.net-", "-orcaslicer.co-" and "-orca-slicer.com-" as these are unofficial and potentially malicious.

Printers

We've mostly standardized on Creality printers – this isn't by any policy, but Creality's printers are generally pretty decent, inexpensive compared to other brands, and very hackable.

- Print Station 1: Bambu P1S (with AMS)

- Print Station 2: Creality Ender 5 Pro (with BLTouch)

- Print Station 3: Creality Ender 5 S1 (with Sonic Pad)

- Print Station 4: Creality Ender 3 Pro

We also have several other printers that need some amount of T.L.C. before they're usable. We may be willing to let these go to a good home if anyone were to ask nicely enough.

General How-To

Drying Filament

It's important to make sure your filament is dry before printing, as filament that has absorbed moisture can be very brittle and will print poorly. There is a filament dryer at the space and here are some times and temperatures to use for various filament materials commonly used:

| Material | Temperature | Hours |

|---|---|---|

| ABS | 60°C (140°F) | 3 |

| ASA | 80°C (175°F) | 4 |

| PETG | 55°C (130°F) | 6 |

| PLA | 45°C (115°F) | 6 |

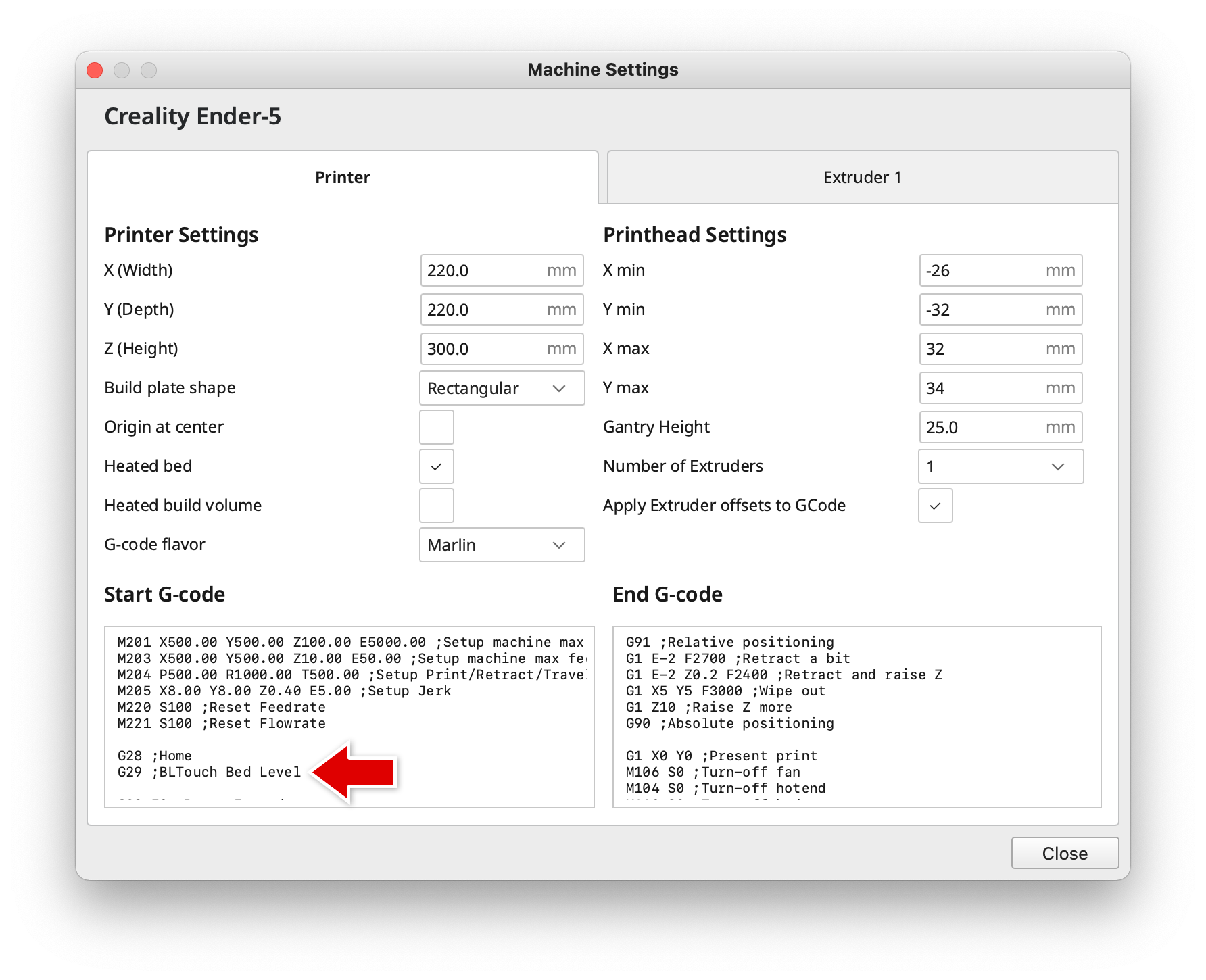

Set up BLTouch in Cura

Our Ender 5 has a BLTouch bed probe installed which needs to be enabled in the printer profile in Cura. After adding the Ender 5 printer, open the machine settings. After the G28 command, add a G29 to enable the bed probe at the start of each print.

Printer-Specific Usage Guides

Print Station 1: Bambu P1S

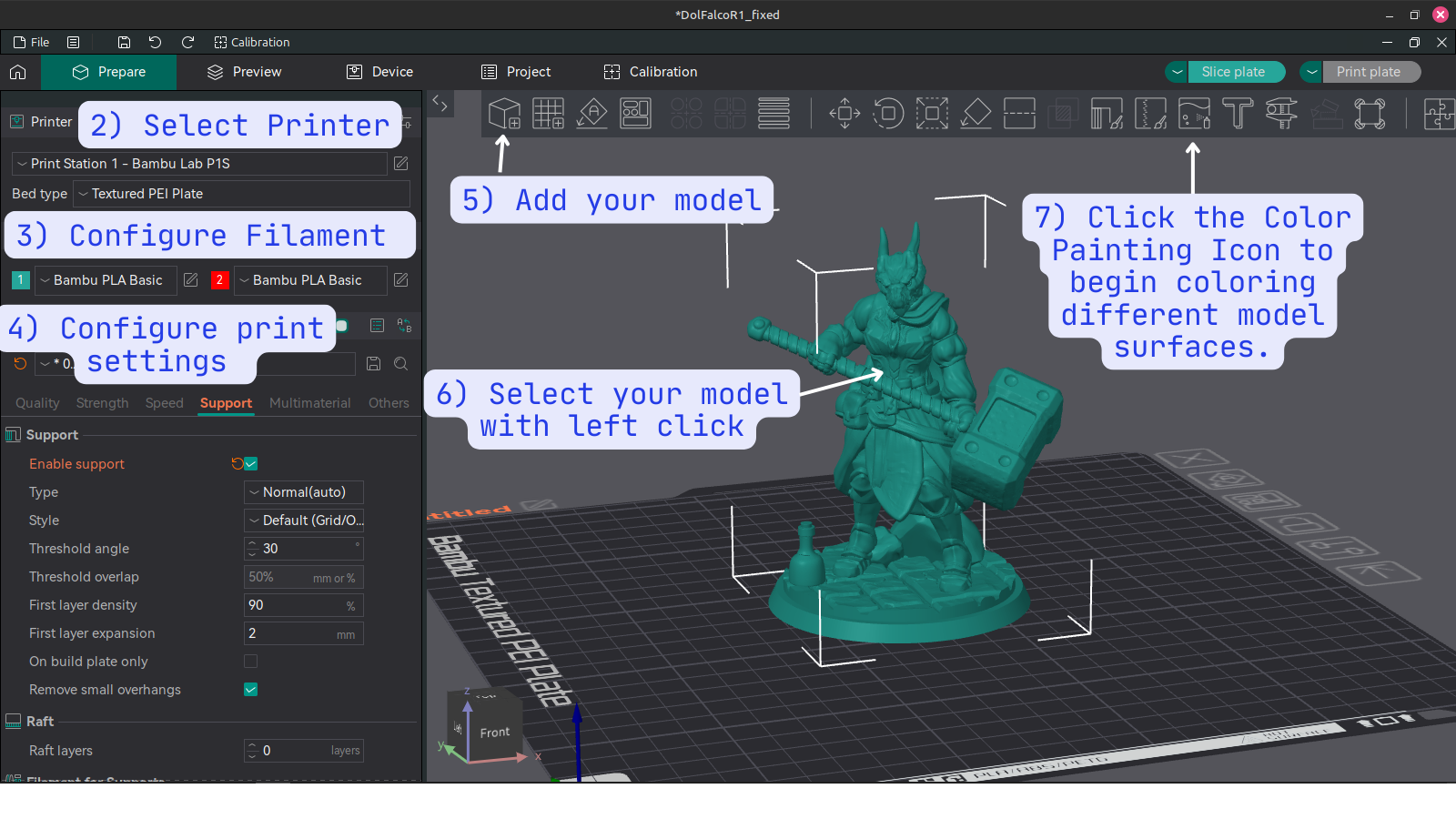

Workflow for Bambu P1S

- Load desired colors / materials into AMS as shown in the video below. Note which slot you put each color in; they are numbered 1-4 from left to right.

How To Load Filament Into AMS:

In Orcaslicer, select or set up a printer profile for the Bambu P1S. If you're at Root Access we recommend using PC Workstation 1 where Orcaslicer is already installed and profiles are set up for all four FDM printers.

Configure filament in Orcaslicer. Click the "+" icon to add another filament spool. The number displayed next to each spool corresponds with the slot number in the Bambu Lab AMS (spool holder). You can change the color icon for each spool in orcaslicer to something closer to the actual color loaded in the AMS to help you keep track of which parts of your print will be which color.

Configure print settings such as infill, wall count, adhesion, and support.

Add your model by clicking the icon shown in the figure below.

Select your model by left clicking it.

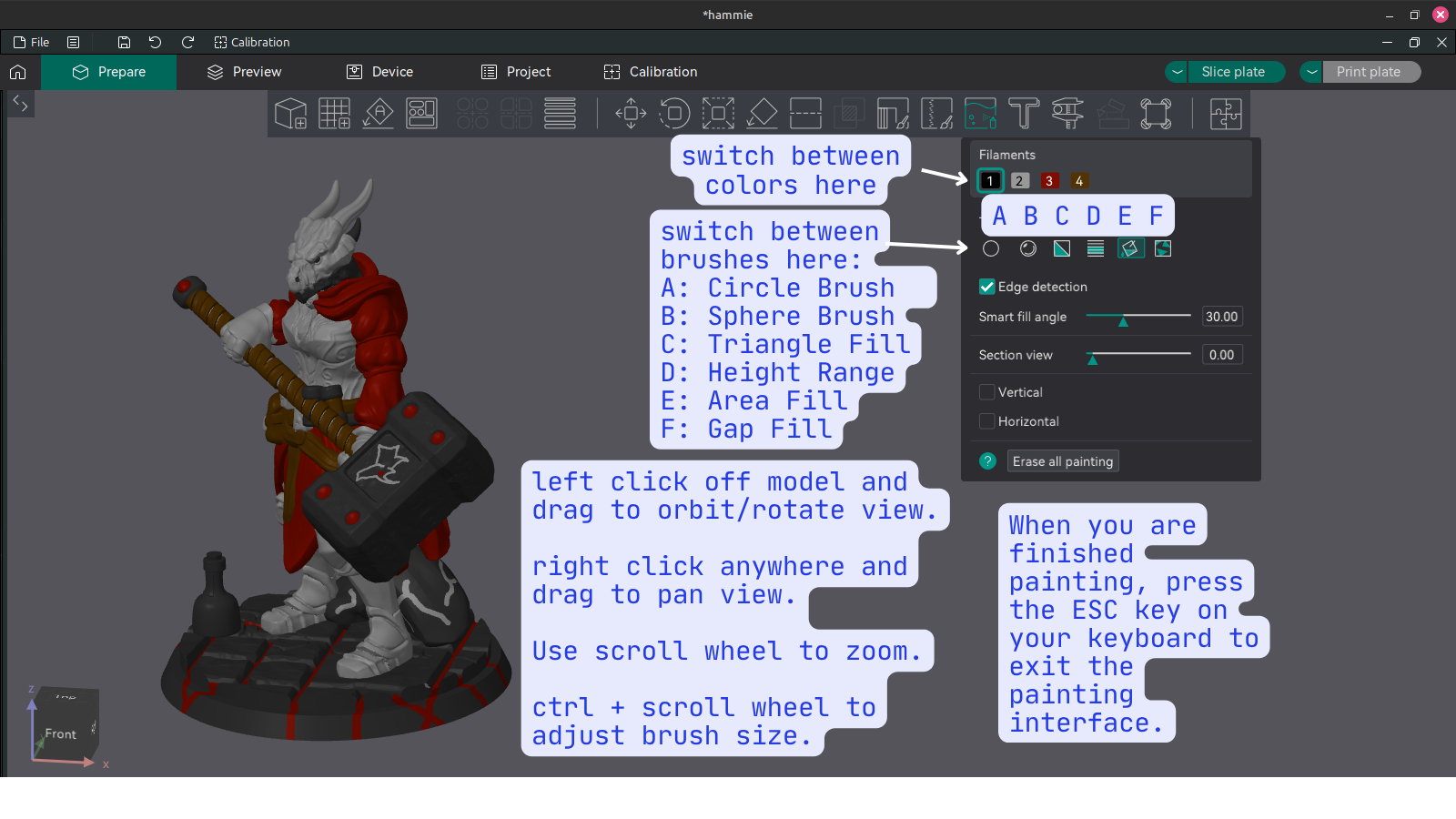

Click the icon shown below to begin painting your model.

8. Use the painting interface to define which surfaces of your model will be printed with which filament spool.

8. Use the painting interface to define which surfaces of your model will be printed with which filament spool.

- Here is a brief description of each brush's function. See image below to find the corresponding icon for each brush.

- A. Circle Brush: A simple freehand brush with adjustable size. Applies to only the single surface touched by the mouse pointer.

- B. Sphere Brush: Another freehand brush that marks any part of the model within the boundary of an adjustable sphere centered at mouse pointer.

- C. Triangle Fill: 3D models are composed of a mesh of small flat triangles. This brush targets them individually.

- D. Height Range: This brush allows you to specify all surfaces within a height range to take on a specific color.

- E. Area Fill: A smart brush that allows you to select and color different areas of your model. To save time, try using this brush first before using the freehand brushes.

- F. Gap Fill: This is not a brush but a tool that applies to your whole model. Adjust the gap size to allow Orcaslicer to automatically detect and fill in small areas between larger areas. This will result in a cleaner look and reduce unnecessary color switching at printing time.

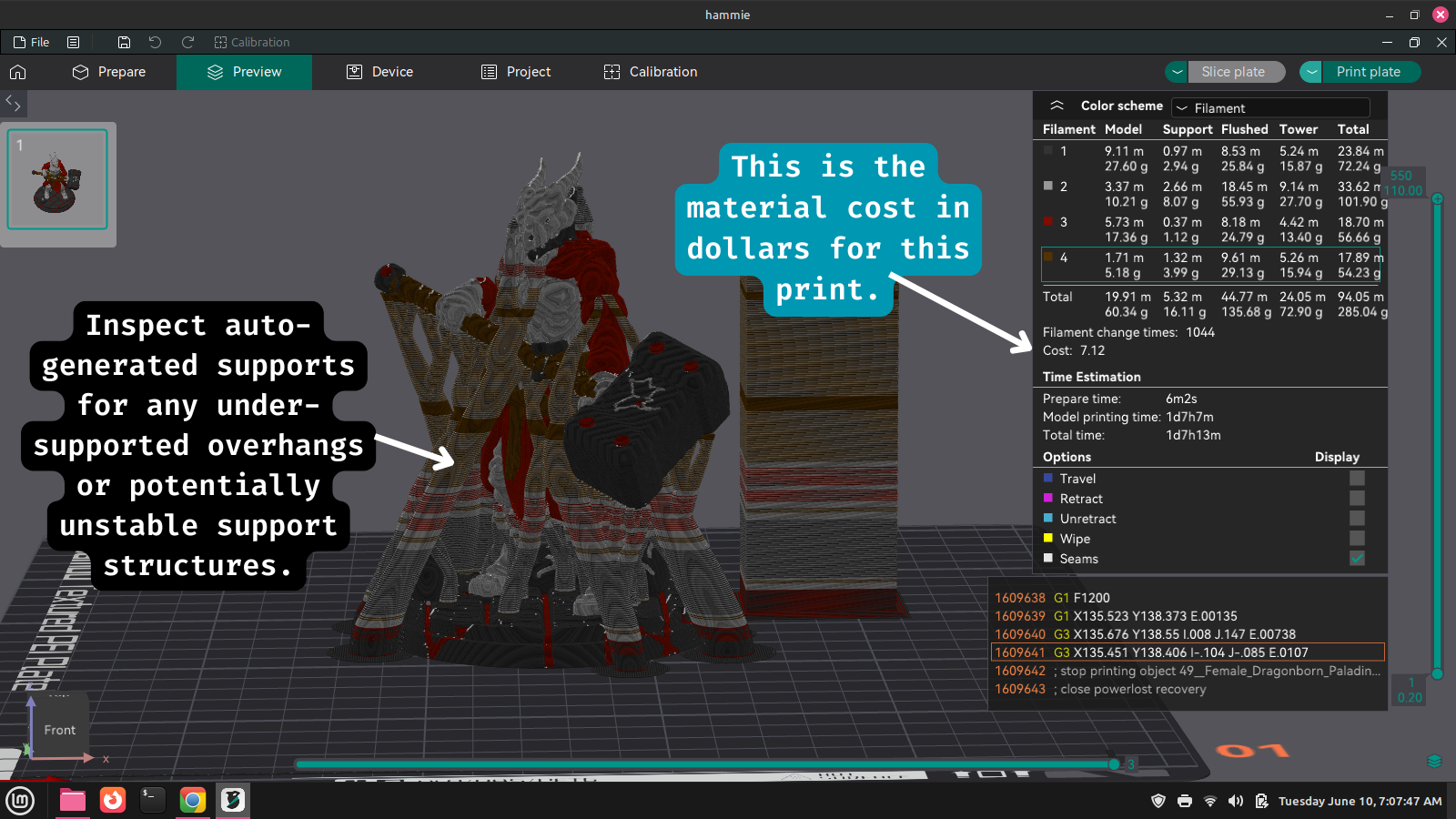

- When you are satisfied with the coloring of your model and all other print settings, click Slice Plate and Orcaslicer will process your model. Look over the sliced model and inspect the supports and any bed adhesion features you have added. Adjust these settings if needed then slice again. Note the cost of the model is displayed among other information after slicing is complete. Remember, materials are not included in your membership so if you used filament from the space please make a donation to cover the cost of the print. To help keep the print area self-sufficient and fund future improvements, we ask that you round up to the nearest dollar. See figure below.

Select "Export G-Code file" from the dropdown menu to the right of the "Slice Plate" button. Export the G-code file to a micro SD card. Use one of several micro SD to USB adapters available in the 3D printing utility area next to Print Station 1. Note the name of the G-code file so you can find it in step 11. Be sure to unmount the micro SD card before removing it to prevent file corruption.

At Print Station 1, insert the micro SD card into its slot on the machine. See figure below. Depending on the shape of your print's footprint, you may want to apply a thin layer of glue from a glue stick to the print bed. Use the directional arrow keys to navigate to the folder icon on the LCD screen. It will take a few seconds for the printer to load the files on the SD card, so be patient. Find your g-code file in the list, hit OK to select then OK again to print.

- The printer will perform a self-calibration and preparation sequence before it starts on your print. It will make several strange noises; this is normal. It's a good idea to stick around to monitor the first few layers at least for any problems such as poor extrusion or parts of the print not sticking to the bed. Once you are satisfied that the print is off to a good start, you can leave it and come back after it's finished. When it's done, allow time for it to cool down, then remove the flexible build plate and bend it to remove the finished print.

And here is the finished model. The supports for the figure's hammer came unstuck from the print bed causing the lower half to separate from the rest. To correct this for a future print I can make it so the supports are on a raft with the main print. This illustrates the importance of checking the auto-generated supports in orcaslicer before printing. A failed print doesn't have to be a complete loss though; for example here I've used hot glue and air-dry clay to turn the mishap into a new feature.

Resources

Guides

- Bed Leveling Guide

- 3D Printer Troubleshooting Guide - MatterHackers

- Print Quality Troubleshooting Guide - Simplify3d

- Ultimate 3D Printing Troubleshooting Guide - 3DSourced